In the contemporary dynamic industrial landscape, companies are continuously searching for ways to boost efficiency and lower production costs. One of the most disruptive technologies having an impact in various sectors is the injection molding process. This cutting-edge manufacturing process allows for the rapid production of top-notch plastic parts and components, making it an invaluable asset for businesses hoping to simplify their operations.

Injection molding services provide a myriad of benefits that can greatly increase productivity and profitability. From reduced lead times to minimized material waste, organizations can utilize this technology for enhanced flexibility and scalability. By implementing injection molding, companies not only enhance their production capabilities but also position themselves for long-term growth in a challenging market.

Grasping Injectable Molding Techniques

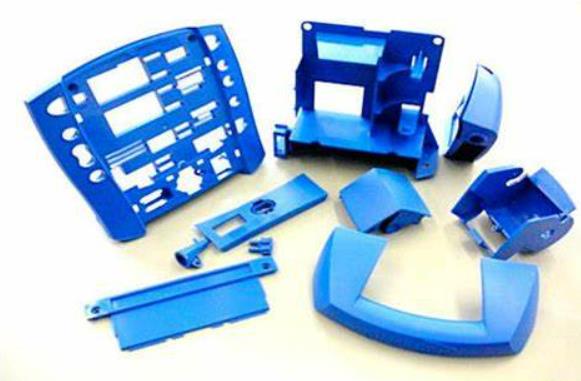

Injection molding is a manufacturing process that consists of the injection of melted material into a form to create various shapes and products. This process is commonly used for fabricating parts made from polymer materials, metallic substances, and ceramic materials. The process starts with warming the selected material until it attains a liquid state, then injecting it under compressive force into a precisely engineered mold. Once the substance cools and cures, the mold is released, and the completed goods is ejected. This method allows for significant precision and reliability, making it a popular choice for many sectors.

One of the notable pros of injection molding is its capability to create difficult shapes with intricate details that would be challenging or not achievable to achieve with alternative production techniques. This capability opens up a wide range of design options, permitting businesses to design tailored solutions that meet particular market demands. Additionally, the effectiveness of the injection molding process enables manufacturers to create high quantities of components quickly, minimizing delay periods and enhancing overall efficiency.

Furthermore, injectable molding services deliver cost-effective production solutions, especially for high-volume orders. The initial investment in molding equipment may be considerable, but the lasting financial benefits gained from lessened material waste and workforce expenses make it a fiscally wise option. As a result, businesses can look forward to a quicker return on investment while maintaining premium quality in their products. This mixture of productivity, customization, and economic viability makes injectable molding an essential method for enhancing company processes in various fields.

Economic Efficiency and Time Saving

One of the most significant advantages of injection molding is its cost-effectiveness. Once the initial setup, including mold creation, is finished, the production of components becomes very cost-effective, particularly for high quantities. The process allows for rapid manufacturing, meaning that manufacturers can produce thousands of identical parts in a fraction of the time it would take using traditional methods. This not only reduces labor costs but also reduces material waste, making injection molding a economically wise choice for businesses looking to optimize their resources.

Additionally, of time saving in injection molding lies in its speed and scalability. The turnaround time for injection molding can be as brief as a few instants, depending on the difficulty of the part. This swift production rate enables companies to meet market needs effectively and react promptly to changes in consumer preferences. For businesses looking to introduce products quickly, injection molding offers a significant advantage over other manufacturing processes that require longer setup and production times.

Additionally, the reliability and exactness of injection molding result in less rework and defects. With high-quality molds, parts are produced with exceptional accuracy, resulting in less need for revisions. This trustworthiness allows companies to optimize their operations, focusing on development and growth rather than ongoing fixes of mistakes. By employing injection molding services , businesses can ensure they maintain affordable rates while delivering high-quality products to their customers.

Sectors and Industries Reaping Rewards from Injection Molding

This molding technique method has become a key aspect across different sectors due to its effectiveness and versatility. The automotive industry significantly benefits from injection molding, where it is used to produce a wide range of elements such as dashboards, bumpers, and inside fixtures. This technique allows manufacturers to design intricate shapes with exactitude, ensuring a ideal fit and high durability, which are vital for automotive safety and efficiency.

Moreover, the retail industry reaping the rewards of injection molding is clear. Items ranging from kitchen utensils to gadget enclosures can be molded quickly and affordably. This technology enables businesses to maintain high standards of quality and uniformity while meeting varying consumer demands. The ability to produce tailored solutions at volume facilitates groundbreaking market products, giving companies a market advantage.

Lastly, the health sector has experienced major advancements due to injection molding services. The creation of medical devices, surgical instruments, and packaging components requires not only precision but also adherence to rigid regulatory standards. Injection molding guarantees that these products can be produced with the required precision and repeatability, contributing to improved patient outcomes and improved healthcare solutions.